My views of knives were once simply that they were sharp pieces of metal used to cut up vegetables occasionally. That has changed. Additionally to knives specifically designed for very precise tasks (e.g. tomato knives), there are other major differences. Which knife style does it resemble? A European-style knife or a Japanese-style knife? Does the knife have a serrated edge or a beveled edge? Does it have a beveled or serrated edge?

As we will see in this article, knives can be manufactured with various surfaces. The flat surface of a blade has that standard texture. The textures, however, can vary on more elaborate knives. Additionally, knives may use textured steel like real damascus knife or may be dimpled or hammered to increase their performance.

Effortless

It is easiest for most manufacturers to produce the flat, smooth steel of the blade. As this is a natural end result of the grinding process, a flat surface can be easily machine polished and made into the blade’s flat.

A problem with a perfectly smooth surface is that food tends to stick to it more readily, especially wet foods, which are most commonly found on the surface. Those who have ever cooked know how irritating it is to scrape bits of minced garlic or tomato off a knife. These surfaces are textured to accommodate this need.

Diminished

Knives with hollow ground are commonly incorrectly referred to as hollow ground knives. Having hollow ground is incorrect since it describes the shape of knife edges rather than grinding hollows into them.

More and more knives are being made with dimples. Knives with hollow dimples, usually near the edge, are commonly found. By trapping air inside the small pits, they prevent food from sticking to the blade and clogging it. After cutting, the food is collected much more easily, and the cuts are smoother and easier.

Heard hammering

Hammered blades have been intentionally dented and textured during manufacturing to give them an old-school look. As a result of the uneven surface, food will not stick to the flat of the blade as it traps air and prevents it from sticking to the dimples. In traditional Japanese knives, especially the expensive ones, this feature is more common.

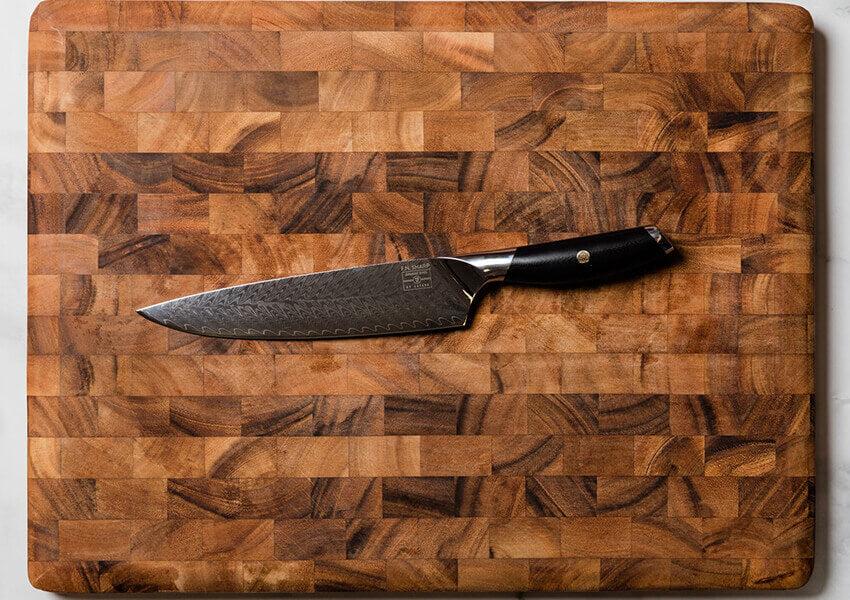

Syria steel

It’s found in several styles of knives, as well as Japanese knives, but it’s most common use is in damascus steel knife set. For knives with cores and edges, Damascus steel is usually wrapped around harder, more brittle steel known as the core steel. Damascus steel usually does not have a smooth surface since it is constructed from folded steel layers. This steel does not have a smooth, hammered or dimpled surface as the steels above. During cutting, food does not stick to the blade because air is trapped in the valleys of the steel.

Comparing textured blades to flat blades

When you need to slice and chop food that doesn’t produce very small pieces, texture blades are the best choice. A flat blade is better for mincing and chopping very finely. The dimples or imperfections of the blade can lodge tiny pieces of food, making them even harder to remove. It’s easier to just scrape off these bits if you have a flat blade.

It is also necessary to take extra care when cleaning textured metals. When cleaning knives, food pieces can not only become stuck, they are also harder to detect. These little reservoirs can also become rusty or discolored due to trapped water.

Although these blades perform exceptionally well for any kind of cutting task, it’s worth having one of them around for making fine cuts that other knives may not be able to handle. Make sure that you only sharpen the slicing knife with a ceramic or glass honing rod if you have both a slicing knife and a cutting knife. An edge can be changed by honing it with a steel rod.

Leave a Reply