You can hardly talk about the making of metals without discussing blast furnaces at some point. These machines are crucial in the making of metals.

For instance, a lot of the pig iron which happens to be helpful in the making of other rigid metals is made using blast furnaces. It will interest you to know that many companies and industries at large depend on the products of blast furnaces.

Here, we are talking about national defense agencies, manufacturers of – automobiles, electrical appliances, players in the metallurgical business, and so many others. It is for this reason that people that rely on these metals need to understand how blast furnaces work and how to ensure they always work properly.

This is why we will discuss the structural composition of a good one in this article. We strongly advise everyone that works in sectors that rely on these machines to keep reading. This is so that you can get the best of your blast furnace; avoid hazards, as well as unwarranted shutdowns.

What Is a Blast Furnace?

This is a kind of furnace that has the metallurgical function of smelting. Smelting has to do with the process involved in the creation of industrial metal using this machine.

More often than not, the kind of metal blast furnaces are used to produce is pig iron. Although it is low in strength as it contains a carbon composition that is very high, it is very important especially because it is used to make other metals.

In other words, pig iron is one of the best intermediate metallic items. This is why various industries are particular about getting theirs from manufacturers that understand the importance of these fragile metals and can offer top-quality.

To achieve this, the manufacturer has to make the best use of a blast furnace. Other than blast furnaces, electric furnaces can equally be used to make pig iron and some other metals. However, the use of blast furnaces is still common and considered a better way by many industry experts.

This is because of the several benefits that it affords – including the quality of products it guarantees if the blast furnace is properly used and maintained. As a result of this, understanding how this age-long metal-making machine operates and how to keep it in the right shape is important.

Although using it to make pig iron is very common, a few other metals can be made using this machine. For instance, copper and lead fall into this category.

Regardless of the kind of metal involved, the machine typically works by forcing or supplying combusted air beyond atmospheric pressure. Just so you know, this is why it is called a blast furnace.

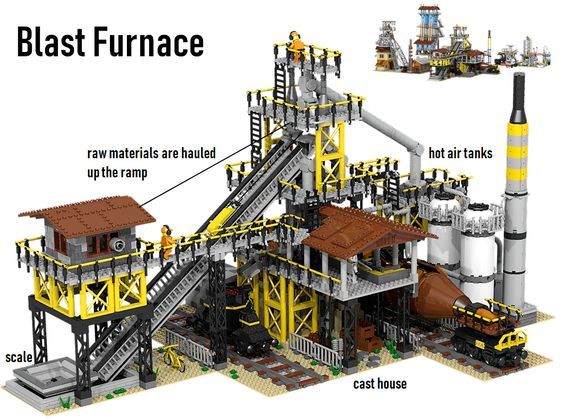

The Structural Composition of a Blast Furnace

People and companies that are involved in the sales and purchase of these machines understand that it is a costly process. As a matter of fact, the price of the least expensive one keeps rising as a result of many things.

So, getting the right one is in the best interest of those getting the blast furnace. This is why they need to have a good understanding of how it should look and function. Usually, the kind of industrial metal to be produced and the quantity are factors that determine this.

We strongly recommend that you hire a professional service provider that is into blast furnaces repairs and installation to help out. This is even if you have in-house professionals that are trained to make the decision. The reason is that you cannot be too cautious when getting a new blast furnace.

So, you should get as much professional help as you can. Also, some of these companies that specialize in the repair and installation of these machines sell/construct them. So, you might want to consider them. Other than the need to hire these professionals in making the right decision, below are some of the structural requirements of blast furnaces at the very least.

The Right Height

The height of the machine is very crucial. This is because it will impact its ability to convert items such as coke, limestone, and ore to the required industrial metal under the right temperature.

Having established that, a blast furnace is expected to be close to 30 meters in height. However, some machines have been found to exceed this, especially in recent times. This is because of the output expected of such.

So, you cannot categorically make 30 meters the yardstick. However, it is expected that the machine should be close to this height at the very least.

The Right Width

Asides from the height, the width also impacts its output. It even determines its durability considering the kind of temperature it is exposed to.

The metal-producing machine is expected to have a diameter of around 10 meters at the very least. The diameter of around 10 meters is about the widest part of the furnace. This is usually the base. Just as was explained above, this is just a minimum requirement as many options in recent times exceed this.

The Right Casting

Blast furnaces do not only do something important for consumers of metals. The amazing thing is how they do it non-stop for the most part. This means that many of them are not shut down except for critical maintenance checks.

The fact is that the casting of the machine plays a huge part in how long-lasting it will be. This is why you should be particular about getting one that is well cast.

Speaking of appropriate casting, the right machine should be cast with heavy plates of steel. But it is much more than this. Considering the kind of temperature it will constantly be exposed to, the choice of steel plates is very important.

The best option is refractory brickwork with a lining that is very thick. Having it cast with such will go a long way in increasing its effectiveness and durability.

Other than this, there should be channels created to water-cool the heavy plates of steel. Once again, this is because of the extreme temperature the machine is exposed to and the need to avoid complications along the line.

For more on the structural composition of this metal-making machine, you can visit: https://studentlesson.com/definition-components-diagram-working-maintenance-of-blast-furnace/

Conclusion

Regardless of the quality of the blast furnace you have, there will be a need to carry out repairs at some point. We strongly suggest that you hire an installation and repair service provider to carry out routine checks.

This is so that things do not get out of hand before you address the situation. These experts have the training and equipment to detect problems long before they cause a shutdown. So, you should engage their services.

Leave a Reply